PROJECT FALCON

dcgeorge.com

The personal website of Douglas C. George.

|

PROJECT FALCON |

dcgeorge.com |

The personal website of Douglas C. George. |

|

Click here to watch the new YouTube video

Click here to see a 3D CAD model that you can zoom, rotate and explode.

Last Revision

January 12, 2011

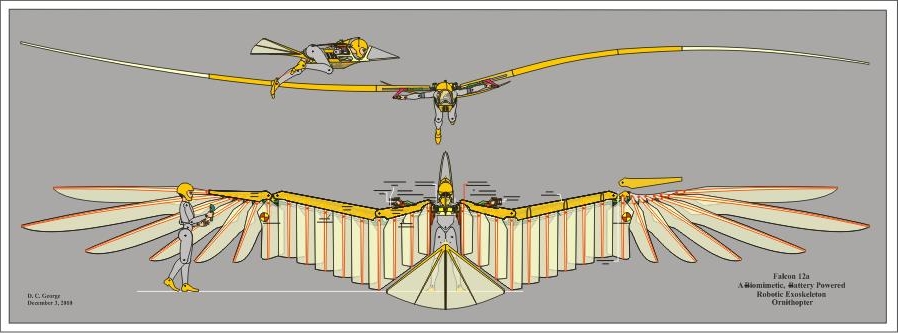

With the advent of carbon fiber composites, expanded foam structures, exotic alloys, computerized electronic control systems and modern, compact power sources, the dream of flying like a bird is possible now.This design is my vision for how it could be built.

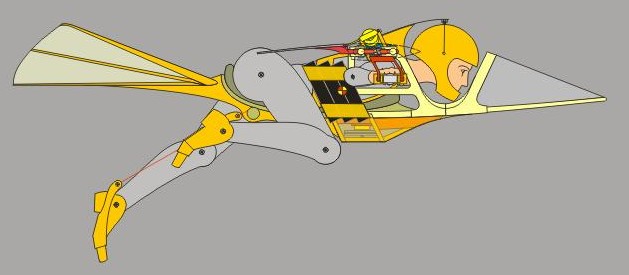

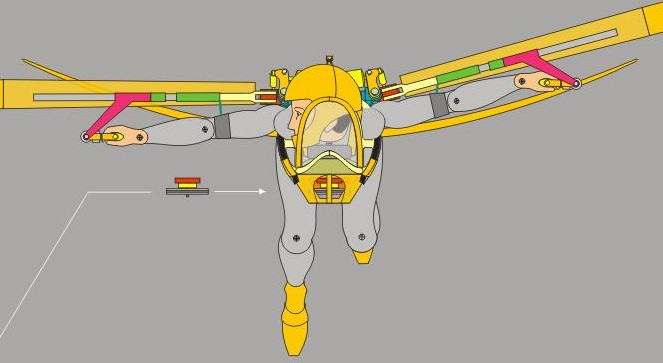

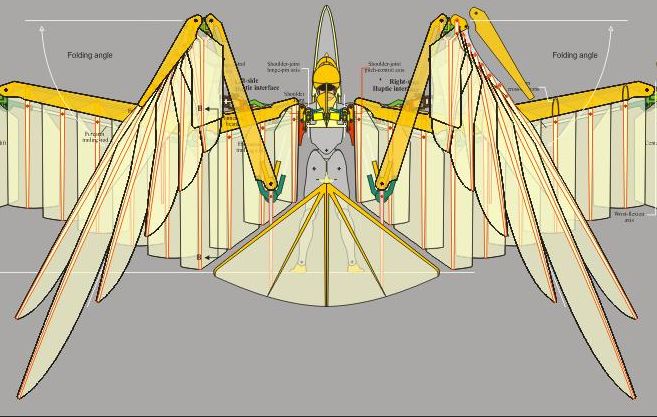

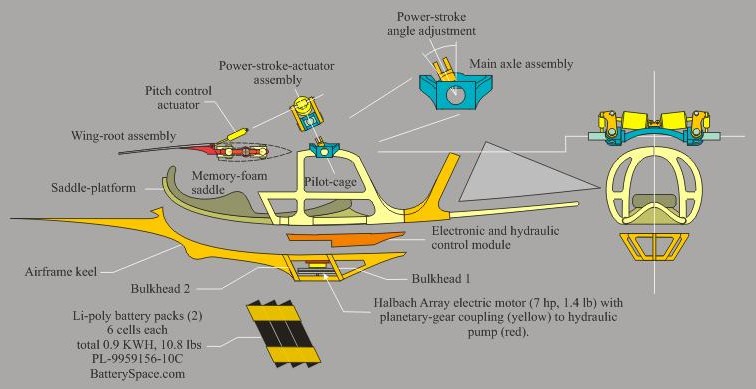

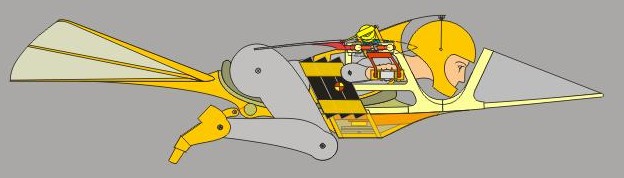

The Falcon is a light-weight, strap-on, exoskeleton aircraft coupled to you through a computer controlled interface. It transforms your arms and hands into bird wings. The wing movements are driven by hydraulic pistons pressurized by a Halbach Array electric motor driven by Li-poly battery packs.

The wings and hydraulic actuator unit are mounted behind your shoulders. You wiggle into the exoskeleton cage, sticking your arms out through the side openings and strap the whole thing down like a backpack. Then, boot up the system, grab hold of the hand grips and you're ready to fly. As long as you hold on to the grips, the exoskeleton tracks your arm and hand movements and responds with corresponding movements of the wings. You can let go of the grips at any time during the flight. If you want to look through binoculars, take some photos or just rest your arms, letting go of the hand grips automatically puts the craft into its default glide mode configuration.

Whether appropriately tethered in a wind stream or training on a simulator, learning to fly will be a matter of learning by feel what works and what doesn't, just the way you learned to walk or swim.

The images on this web page are screen shots taken from a large master drawing.

To see a huge, a high resolution, image of the full drawing that you can scan and zoom into, click on the link below.

Click here to view the full, high resolution image (3.55 MB 1/7/2011).

For those who might be interested in a detailed evaluation study of the Falcon 12a, click on the following link. This study was undertaken in an attempt to determine the feasibility of powering the craft using an electric motor and battery packs. The main evaluation tool is the Excel Falcon 12a Performance Evaluation Spreadsheet.xls which you can download and play with or even use to design your own ornithopter.

Click here to view the study.

The version 12a incorporates the use of artificial feathers to achieve a relative high glide ratio of around 20:1. A high glide ratio generally requires high aspect ratio wings and the wing's pinion feathers serve that purpose. In addition, feathers maintain their aerodynamic shapes regardless of how much the wings fold up during flight. Another advantage of feathers is that they can be easily approximated by simple swept-back trapezoidal shaped wings which allows the use of an airfoil simulator to predict the wing's lift production. Here is a link to the wing drawing used for the lift simulation.

The Falcon's hydraulic system pump is powered by a Halbach Array electric motor and energized by two Lithium-polymer battery packs. These new technologies appear to provide an ideal combination of power and light weight.

Given the above developments, it was decided that a rigorous evaluation of the whole idea was called for. To this end, a highly detailed, numerical feasibility study (linked to above) was undertaken to see if the approach might prove to be possible.

Edward Tufte's video, taken at 300 frames-per-second, of geese taking flight reveals that the flapping flight of birds is less complicated than previously thought. Birds employ a relatively simple scheme to accomplish what appears to be a complex set of motions.

The power-stroke of the flapping cycle is simple and straight forward; the wings sweep downward and forward while stretched out flat with the joints locked.

During the backstroke, a bird simply relaxes its wrist joints and allows its hands to fall limp while simultaneously folding its wings inward. The relaxed hand-sections, caught up in the wind stream, are quickly lifted and thrown backward requiring little or no effort on the part of the bird.

Further simplifying the process, as the wing folds, a parallelogram arrangement of the arm bones keeps the hand and humerus sections aligned.

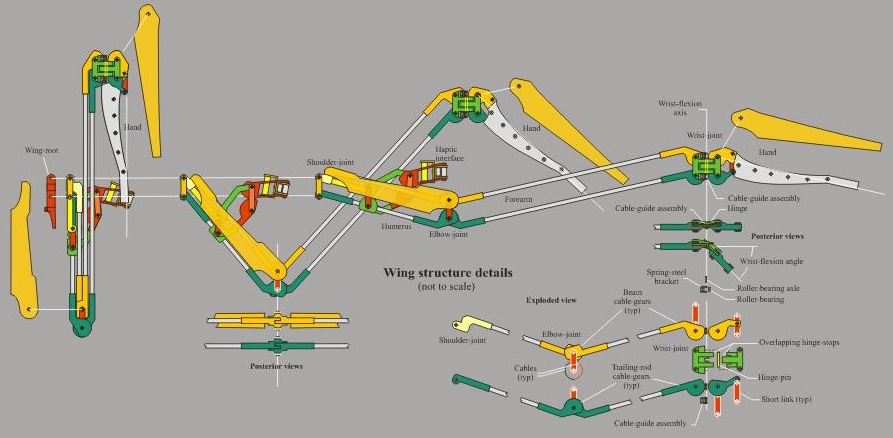

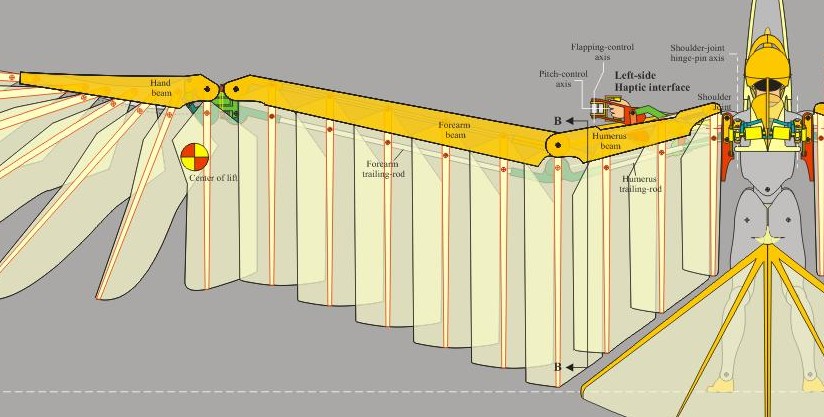

As shown below, the Falcon wing forearm includes such a parallelogram structure. The illustration shows the wing in three stages of extension. Note that the hand section stays parallel to the humerus section in all three positions.

Unlike in a bird, the humerus section in the Falcon wing is also a parallelogram mechanism. Its purpose is to prevent any forward or backward sweep of the wing during the folding process. As will be explained below, this makes the power-stroke function much simpler and provides for a clean separation between the three control functions.

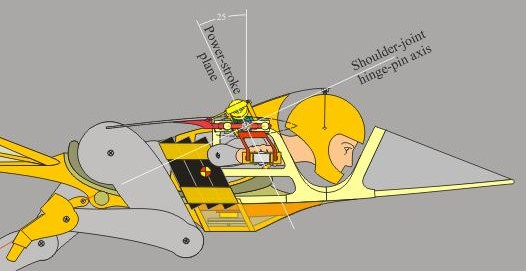

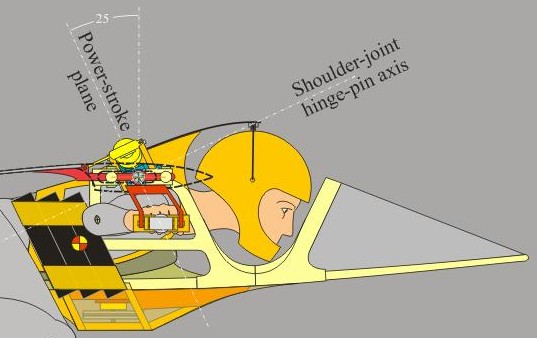

Flapping motions of the wing (the power-stroke and backstroke) are confined to a single plane called the power-stroke plane (illustrated below), determined by the tilt of the shoulder joint axis. The power-stroke plane is both down and forward (as it is with birds).

This arrangement allows for a mechanically simple power-stroke in which the stroke angle can be adjusted for optimal efficiency and the entire flapping function is cleanly separated from the wing-folding and pitch-control functions. More importantly, it allows the entire flapping sequence to be powered by only one hydraulic piston per wing.

A bird's hand section is equivalent to the business end of a boat's oar, driving the bird forward as well as upward. The Falcon's hand section, as in a bird wing, will be designed to twist during a power-stroke to tilt the lift vector more forward than it is for the inner two wing sections. In the bird wing and the Falcon's wing, the inner two sections maintain a relatively fixed angle of attack to the wind and so provide varying amounts of lift during all phases of the flapping cycle.

All of these factors add up to a simplified flapping cycle for the Falcon that insures a clean separation between the various power and control functions.

Birds fold and extend their wings during flight for many reasons. They fold them to gain airspeed, to dump excess forces, to maintain headway in a stiff wind and, as mentioned, they fold them during the backstroke phase of the flapping cycle.

Since the lift and drag forces acting on the wings are generally perpendicular to the force needed to fold them up, our ornithopter wings are folded up using only the pilot's arm muscles.

The wings are tension loaded to maintain full extension. The tension will be adjusted to allow the wing folding process to be done by arm-power alone. You simply pull the hand grips inward to fold the wings and relax your arms to let the wings spring back to their extended positions

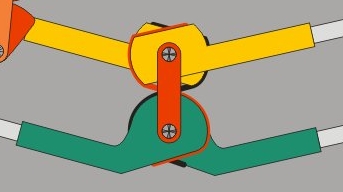

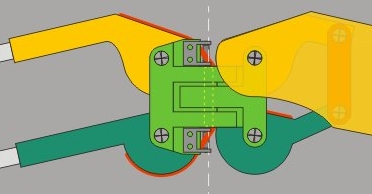

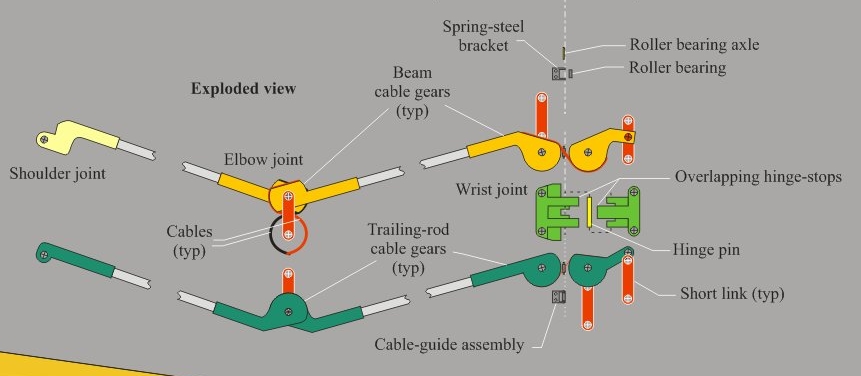

The wing sections are coupled to each other by pulley-like devices called cable-gears that are built into the ends of the long parallelogram links. The devices function just like regular gears to keep the folding angles equal but are lighter in weight. The left illustration below shows the cable-gear arrangement of the right-wing elbow joint. The red cable wraps around the gear on the forearm beam and crosses over to the trailing-link gear of the humerus. The black cable similarly connects the other two gears. The cables cross in a figure-eight fashion at the center of the joint. In the wrist joint (right illustration below), in order to make space for the flexion hinge, one cable joins beam to beam and the other connects the two trailing-links.

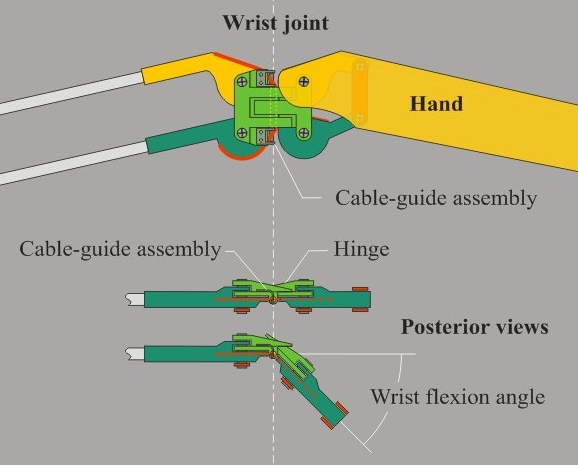

The Falcon's wrist joints incorporate hinges that allow the joints to flex downward even while the wings fold and extend. The drawing below shows a top view and two posterior views of the joint. The hinge incorporates two cable-guide assemblies with small roller bearings mounted in spring steel brackets to guide the cables over the bend as the joint flexes. In this way, the wrist flexion and wing folding functions are independent and can be controlled individually and simultaneously.

Here is a view of the whole wing structure that shows more details of the joint parts.

At the start of a strong backstroke, the wrist-joint hinge will unlock (the locking mechanism isn't shown yet) and let the outer wing section drop, relieving the humerus of the task of lifting the entire wing up as a stiff unit. This causes the rotation of the humerus and forearm to accelerate. As the humerus and forearm continue to rotate, the loose hand-section is dragged along by its proximal end while being lifted and thrown backward by the air stream. During this process, the pilot pulls on the hand grip to fold up the wing, which further accelerates its angular rotation. At the apex of the backstroke, the wing flattens out and the hinge locks up again.

This combination of wrist flexion and wing-folding will enable the wing-flip (the backstroke) to happen very quickly using little or no energy.

To allow for soft, slow back-swings and prevent the wingtips from collapsing inadvertently, the wrist joint hinges remain locked at all times except at the beginning of a strong back-swing.

The wings will employ damping mechanisms (to be designed) to soften the shock encountered as the wing sections snap back into the locked, flat-wing configuration at the top of the backstroke.

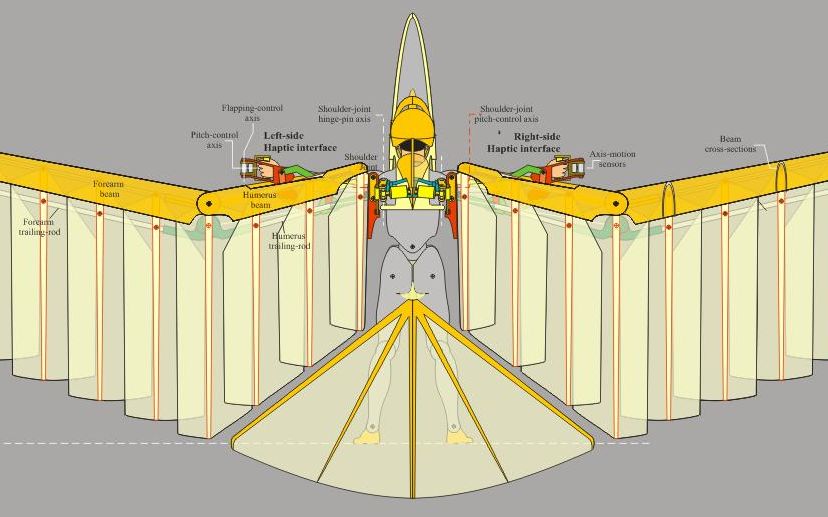

The shoulder-joint accommodates three independent functions: flapping, folding and pitch/roll-control.

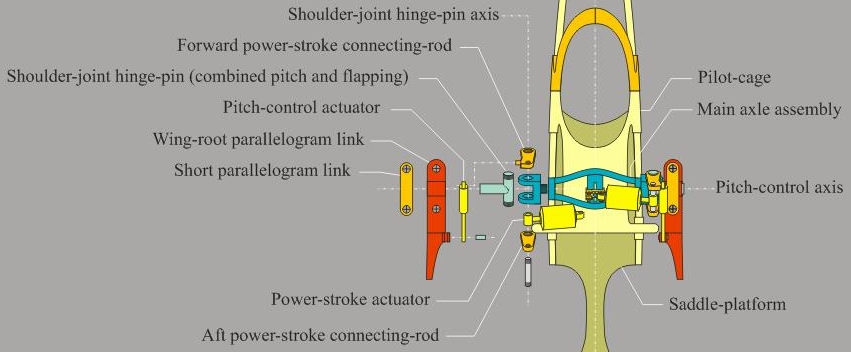

The power-stroke and backstroke of the flapping cycle are driven by a single hydraulic piston for each wing. The pistons are double-acting, unbalanced actuators that are driven in both directions. They produce more force in the pushing direction (for the power-stroke) and less in the return direction (for the backstroke). The pistons are 2 inches in diameter operating at 3400 PSI and act through 3 inch connecting rods coupled to the shoulder-joint hinge pins. The system can produce about 2670 foot-pounds of torque at the shoulder joint. If the center of lift is located five feet out from the shoulder joint and the total weight is 288 pounds (for both the craft and its pilot), it would take 1425 foot-pounds of torque to hold the wings flat while gliding. The excess torque (1245 foot-pounds) is available for the power-stroke. The actuators are attached to the main axle assembly as shown in the illustration below and coupled to the hinge-pins through forward and aft connecting rods.

On each wing, a smaller pitch-control actuator is attached between the top of the forward connecting rod and the wing-root parallelogram link (shown in red).

Pressure for the hydraulic system will be supplied by a high-pressure pump driven by a seven horsepower Halbach Array electric motor currently under development by LaunchPoint Technologies. The motor will be energized by a pair of Lithium polymer battery packs with a total capacity of 0.9 kilowatt-hours. Control will be provided by a small, on-board computer coupled to the pilot through haptic interfaces. Such systems are presently under development or being manufactured by Berkeley Bionics in Berkeley, CA. and are employed in their Human Universal Load Carrier Exoskeleton. The operator controls their exoskeleton by simply walking (or running) in a normal fashion. No other conscious effort is needed. In the Falcon, you will simply move your arms and hands in appropriate flapping motions to control the system and, likewise, no other conscious effort will be needed.

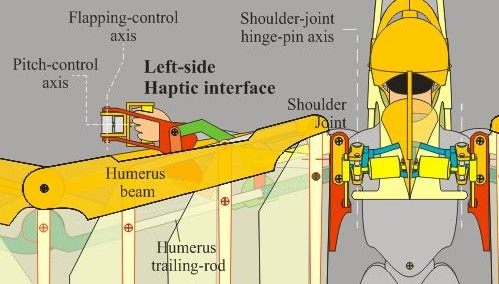

A haptic interface is a sensing and feedback mechanism that acts as the interpreter between a human and a robotic device. The interface senses the human's actions and returns information about the state of the device. The Falcon employs two such interfaces, one for each wing. Each interface includes a hand grip, two sensors and a small parallelogram.

Wing motions are initiated by either lifting, rotating or pulling on the handgrips.

As shown below, the hand grip and sensors are mounted on a small parallelogram attached to the larger parallelogram of the wings' humerus section. The same cable-gear devices as used in the wing joints are used in the interface joints to force the interface and your arm to mimic the folding motions of the wing. The hand section of the interface tracks both the horizontal rotation (radial deviation) of the outermost wing section and imitates its vertical flexion. Because the human wrist has a lesser range of motion in the horizontal plane, the radial deviation of the interface's hand-section is less than the rotation of its counterpart in the wing.

The only connection between you and the aircraft (other than being strapped in) is through the two hand grips. You simply grasp the hand grips and move your arms and hands in an appropriate manner. The haptic interfaces detect your motions and direct the hydraulic actuators to move the wings in a corresponding manner. All the while, you receive constant feedback about the configuration of and forces acting on the wings.

Feedback is achieved in two ways. First, the centers of the joints of the small parallelograms are closely aligned with those of your wrist and elbow joints. This insures that your arm positions and motions coincide with those of the wings. The other means of feedback has to do with how the hand grips pivot. When the wing begins to swing upward, the outer section relaxes and bends downward. When you lift up on a hand grip to initiate the back-swing, the fact that it is hinged distally to your hand, causes your wrist to, likewise, bend downward. The two motions coincide. In this manner, you get feedback with no actual linkage between your hand and the wing's hand section.

Flapping Control: An electronic sensor (shown in gray in the drawing above) mounted on the flapping-control-axis of the hand grip detects vertical motions of your arm and activates the large actuator to move the wing in the corresponding direction.

Pitch and Roll Control: Rotating the hand grips about their pitch-control axes cause the aircraft to either pitch or roll. Sensors aligned along the pitch-control axes of the interfaces detect those rotations and direct the small actuators to rotate the wings about their long axes accordingly. Turning one grip at a time causes the craft to roll. Turning both grips in opposite directions results in a more extreme roll. Rotating them in the same direction will result in pitching the nose either up or down.

Yaw Control: Like with birds, our ornithopter has no direct yaw control that is independent of motion around the other two axes. Rotation of a hand grip on one wing to initiate a roll, for example, will naturally include "adverse yaw" as the pitched wing is dragged backward due to the added drag on that side. If the right hand grip is rotated for a downward pitch, the aircraft will roll to that side and the right wing will be dragged backward, resulting in a properly banked turn.

The wings are built in three sections: the humerus, the forearm and the hand. As shown below and in previous illustrations, all three sections are parallelogram mechanisms comprised of an expanded-foam beam forming the leading-edge and a hollow trailing-rod positioned just aft of the beam. Short links at each end complete the parallelograms, connecting the leading-edge beams to their respective trailing-rods. For added strength, the leading-edge beams include embedded hollow rods. The wings are made made progressively thinner and more flexible approaching the tip.

As a wing folds and extends, the distance between the leading-edge beam and its trailing-rod varies. A hollowed-out slot in the beam accommodates these variations.

As described earlier, wing folding is controlled by pulley-gear devices. At each elbow joint, one pulley-gear is integral to a beam and the mating gear is integral to the trailing-rod of the adjacent section. In the wrist joint, one cable connects the two beams and the other cable connects the two trailing-rods.

Unlike previous versions, the Falcon 12a wings are covered with feathers. This change was made for several reasons, the main one being that, with feathers, a higher glide ratio is possible because each pinion feather is a high aspect ratio wing. Another big reason is that, unlike with a membrane-covered wing, feathers don't lose tension and change their airfoil shape as the wing folds up. Each feather consists of a central quill sandwiched between two thin aerodynamic surfaces. The quills are hinged to both the leading edge beam and its trailing-rod and, therefore, their alignment doesn't change during the wing-folding process.

The fuselage, illustrated below, includes a cage that incloses the pilot's torso and supports the wings and actuator units, a saddle platform, a thick, memory-foam saddle, a keel and two bulkheads. The bulkheads enclose the electric motor with its planetary-gear coupling (yellow) and hydraulic pump (red). The battery packs are mounted to the sides of the pilot cage. Control modules for the electronics and hydraulics are mounted to the bottom of the saddle platform on either side of the keel. The forward section of the fuselage includes a windshield and canopy.

Not that it would ever be needed, of course, but a skid-plate is mounted to the bottoms of the bulkheads just in case you stumble during a landing.

To save you from getting a tired neck, your helmet is suspended from a spring mounted, gimbals-like device that allows full freedom of head motion. Your chin rests on a foam pad built into the helmet. The mounting structure behind the head doubles as a neck protection aid in case of accidents.

The tail structure is fixed and non-articulated. It provides pitch stability for the aircraft in its default glide mode.

How much one will use one's legs while flying is an open question. Primarily, you will need them to be free for a running takeoff and for landing. However, during flight, your legs will provide significant weight-shifting to maintain a stable attitude or to enhance maneuvers---especially at low speeds. During a take-off, when flapping motions are most extreme, birds noticeably shift their legs down and backwards during the backstroke and shift them up and forward during the power-stroke. The reason for this is to maintain level flight. Moving the wings forward shifts the center of lift forward which would result in an upward pitch, so the bird compensates by shifting its legs (and its center of gravity) forward to match the changing center of lift. The backstroke moves the center of lift aft-ward, causing the bird to dive, so, it shifts its legs to the rear to compensate. The same conditions would prevail with our ornithopter so, while flapping the wings, you would, likewise, constantly shift your legs forward and backward to compensate for the changing center of lift.

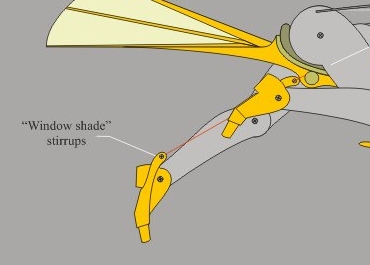

If the legs are left to simply dangle, the pressure on the groin area in contact with the saddle would quickly become uncomfortable (the "dangling legs problem"). To alleviate the condition, the Falcon includes "window shade" stirrups for you to stand on to lift your body weight off the saddle (like standing on the pedals of a bicycle).

The stirrups (shown in the illustration above ) are attached by cables to spring-loaded drums. As with window shades, the drums allow the stirrup cables to extend but automatically lock to prevent the cables from winding up. If you give the stirrups a quick tug, the drums unlock and the springs try to wind up the cables. If you do this and relax your legs, the springs will draw your legs up into the folded position shown below. This folded-leg position is the default glide-mode position in which the craft is balanced for a stable glide.

You can extend your legs at any time. The more you straighten them, the tighter the springs are wound. The stirrup cables become fully taught just before your legs are completely straight. Fully extending your legs, then, will lift you an inch or so off the saddle and free up your legs for a running takeoff or a landing.

Although it can't be ruled out, it's probably not possible with this ornithopter to take off in still air on level ground. Most likely, takeoffs will require a gentle headwind or a sloping surface. Simulator studies indicate that, for an aircraft with this wing area, 288 lbs of lift is obtained at 14 MPH. Since humans can easily run at well over this speed, a running takeoff down a slope is well within the design envelope. Landing would be a matter of gliding down at the slowest possible airspeed and performing a stall maneuver at the last second, just as your feet touch the ground.